Epoxy resin floors are a popular choice for commercial and industrial settings due to their durability, versatility, and aesthetic appeal. However, with various types of resin flooring available, it can be challenging to decide which option is most suited to your business’s specific needs. Considering the nature of your business and the workplace activities is a significant factor: in healthcare clinics, for example, hygiene is non-negotiable, but in commercial kitchens heat resistance is also necessary.

Each resin flooring option presents its own benefits and drawbacks, so it is essential to consider the performance requirements and demands of each, rather than solely focusing on cost. In this article, we’ll outline the properties and benefits of three types of resin flooring: epoxy, methyl methacrylate, and polyurethane (PU).

Epoxy Resin Flooring

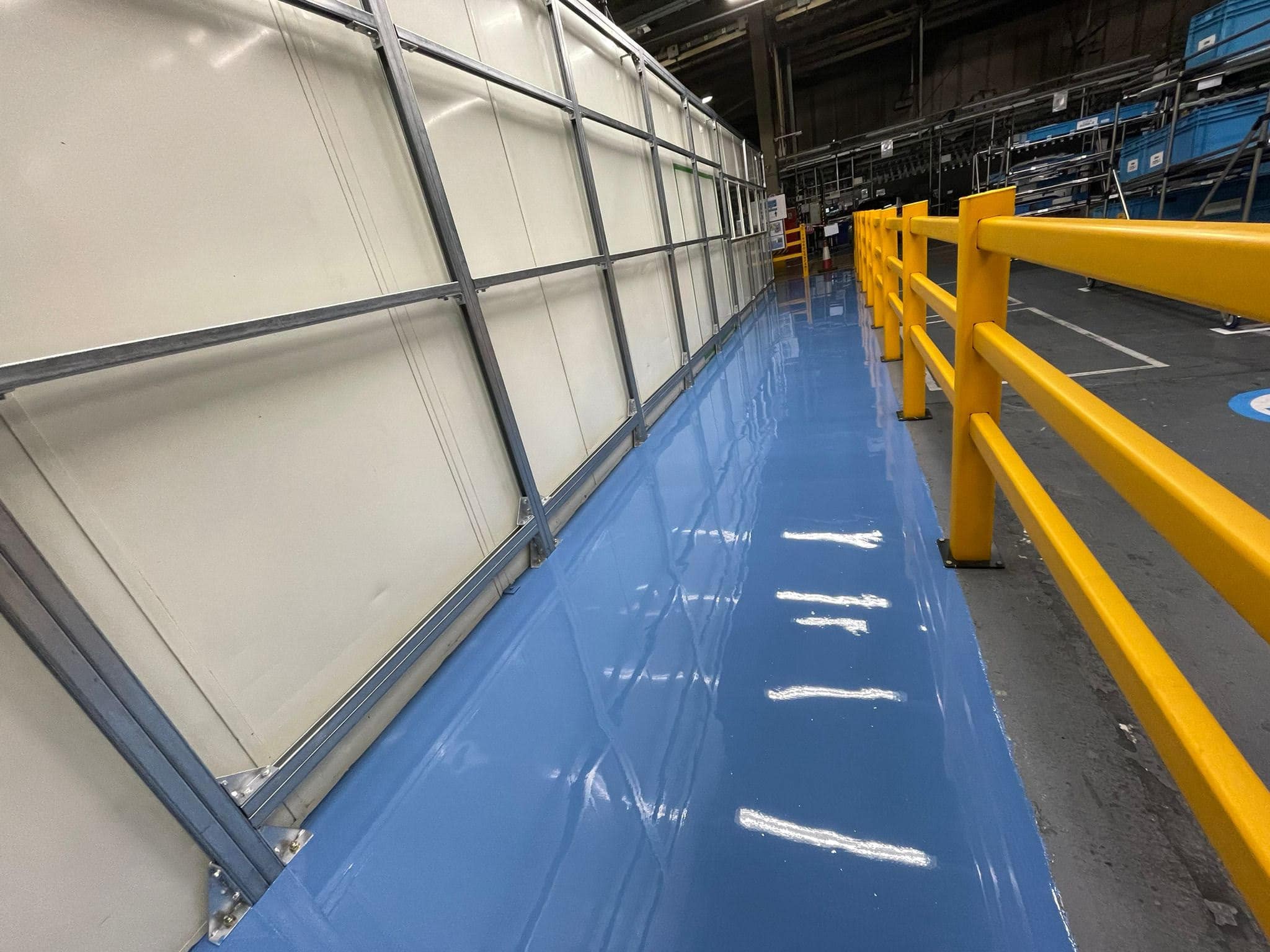

Epoxy is the most widely used and well-known type of resin floor in the UK, offering exceptional performance and durability, and is typically the first choice for electrical conductive applications. Epoxy resin comes in various forms, including coatings, toppings, and screeds, each with its own benefits based on its usage. Additionally, epoxy resin flooring is highly resistant to chemicals and, in many cases, is the most economical option.

However, if epoxy flooring is damaged it must be fully replaced, and it also has the longest cure time of all resin flooring options, which can significantly impact operations during repair or replacement.

Methyl Methacrylate Resin Flooring

Methyl methacrylate (PMMA), or fast-curing resin floors, are the quickest to install and offer several design choices. For example, they can be laid to provide a sleek and silky look or a textured appearance, and can also incorporate decorative flakes, anti-skid, or quartz finishes. They are extremely resilient and can withstand hard impacts, abrasion, and chemical spillages without being damaged.

The rapid curing speed of PMMA resin floors, even at 0°C or below, make them ideal for refurbishment projects where time and efficiency are crucial. Also, these floors are easy to repair and upgrade, offering high levels of customisability to suit your business’s unique aesthetic and functional requirements.

Polyurethane Resin Flooring

Polyurethane resin flooring is as resistant to impact, abrasion, and chemical damage as PMMA, but its strength lies in its ability to withstand high temperatures and direct heat. Therefore, it is an ideal choice for food production facilities, such as commercial kitchens and bakeries, and areas where hot trolleys are left to cool. PU resin flooring is also highly versatile and available in numerous finishes.

However, it is important to note that PU resin floors take significantly longer to cure than PMMA resin surfaces due to their thermoset properties, which could lead to increased operational downtime during installation and repair.

Unsure Which Resin To Choose? Speak To Our Experts Today.

If you’re unsure which type of resin flooring is best suited to your business’s needs, the experienced and knowledgeable team at ARTI can provide you with expert advice to make the right choice. Simply call us today on 01332 215310 to tell us about your next resin flooring project.